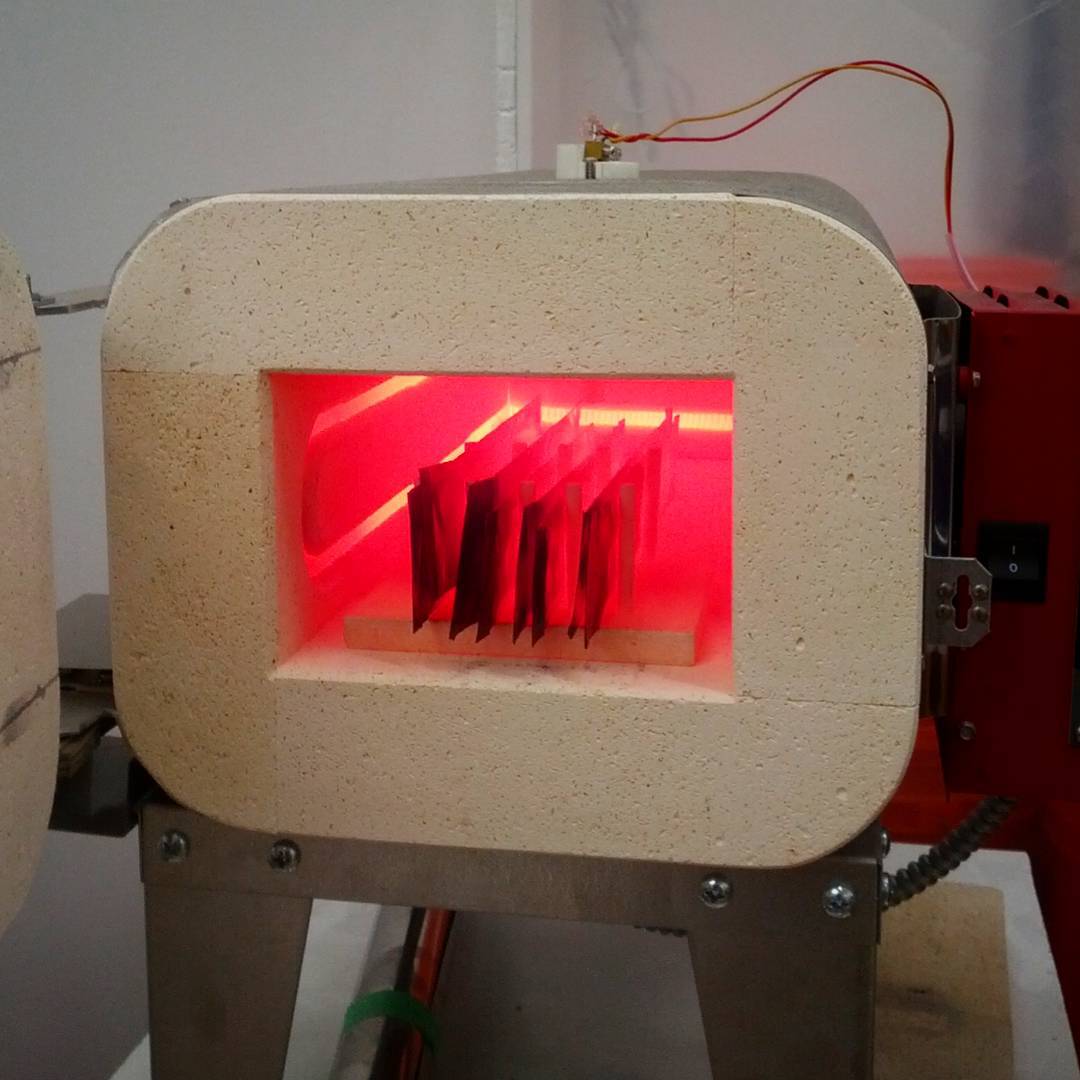

Heat-treating prototype blades!

Doing heat treat today for the prototype batch of knives, immediately after this photo was taken I donned thick leather gloves and IR protective glasses and then removed all the blades using tongs so they could be hung up to air cool.

I always forget how long heat treatment takes!

At least an hour and a half to 2 hours for the kiln to get up to full temperature, then 35 minute soak time at 1775°F, then out they come for the air quench, usually takes 10-15 minutes before they're cool enough to handle. Then first temper for 2 hours, then one hour in sub zero treatment, them second temper.

All up time in the past was usually close to 12 hours because you have to wait for the kiln to cool before tempering and so on. Should be faster with the 'frankentoaster' but it will still take 8+ hours most likely!

Worth it given how well the blades come out!

I have an idea I've been kicking around for a kiln that will do an automated compressed gas quench as part of the cycle, which would make the whole process efficient and consistent. Maybe in a few months I'll get cracking on that!

#knifeclub #knifemaking #knife #knifemaker

Photo by Aaron Gough on July 07, 2015.

See the original post and comments on Instagram

I always forget how long heat treatment takes!

At least an hour and a half to 2 hours for the kiln to get up to full temperature, then 35 minute soak time at 1775°F, then out they come for the air quench, usually takes 10-15 minutes before they're cool enough to handle. Then first temper for 2 hours, then one hour in sub zero treatment, them second temper.

All up time in the past was usually close to 12 hours because you have to wait for the kiln to cool before tempering and so on. Should be faster with the 'frankentoaster' but it will still take 8+ hours most likely!

Worth it given how well the blades come out!

I have an idea I've been kicking around for a kiln that will do an automated compressed gas quench as part of the cycle, which would make the whole process efficient and consistent. Maybe in a few months I'll get cracking on that!

#knifeclub #knifemaking #knife #knifemaker

Photo by Aaron Gough on July 07, 2015.

See the original post and comments on Instagram