Updates

CNC Tooling...

All the tooling for making the blade and tang of the Resolute MKIII.

All tooling is solid carbide except the 60° dovetail cutter. All tooling is AITiN coated except the reamer and dovetail cutter.

The blade will come off the machine profiled and deburred front and back. I'm tooling up over the next few days to partially mill the bevels on the machine as well, the tip of the bevel will be finished by hand on the belt grinder.

#knifeclub #knifemaking #knifemaker #cnc #instamachinist

Photo by Aaron Gough on June 15, 2015.

See the original post and comments on Instagram

All tooling is solid carbide except the 60° dovetail cutter. All tooling is AITiN coated except the reamer and dovetail cutter.

The blade will come off the machine profiled and deburred front and back. I'm tooling up over the next few days to partially mill the bevels on the machine as well, the tip of the bevel will be finished by hand on the belt grinder.

#knifeclub #knifemaking #knifemaker #cnc #instamachinist

Photo by Aaron Gough on June 15, 2015.

See the original post and comments on Instagram

I am now a full-time knifemaker!

Exciting news guys! As of today I'm going to be making knives full time!

It's really awesome to be able to take something that I'm so passionate about and tackle it full time!

Just wanted to take a minute and say thank you to all the people who have supported me, all my customers and everyone who has been following along as I've gone through this knifemaking journey! Your support and patience is hugely appreciated!

My focus over the next few months is going to be getting knives ready for all the people on my backorder list. After that knives will become available to all the people on my mailing list! Will be making a large batch of Resolutes every month from now on!

Very excited guys! This is going to be a lot of fun!

#knifeclub #knifemaking #knives #customknives #customknife #usnstagram

Photo by Aaron Gough on June 12, 2015.

See the original post and comments on Instagram

It's really awesome to be able to take something that I'm so passionate about and tackle it full time!

Just wanted to take a minute and say thank you to all the people who have supported me, all my customers and everyone who has been following along as I've gone through this knifemaking journey! Your support and patience is hugely appreciated!

My focus over the next few months is going to be getting knives ready for all the people on my backorder list. After that knives will become available to all the people on my mailing list! Will be making a large batch of Resolutes every month from now on!

Very excited guys! This is going to be a lot of fun!

#knifeclub #knifemaking #knives #customknives #customknife #usnstagram

Photo by Aaron Gough on June 12, 2015.

See the original post and comments on Instagram

Using my new Haimer 3D sensor!

Checking and calibrating the backlash compensation on the VMC! Looks pretty well dialed in at this point.

I really need to get a little tripod for my phone... #cnc #instamachinist #machineshop

See the original post and comments on Instagram

I really need to get a little tripod for my phone... #cnc #instamachinist #machineshop

See the original post and comments on Instagram

Replacing a Fadal thrust bearing.

This is where I spent basically the whole day, replacing the X axis thrust bearing on the VMC!

I did some tests this morning to find the cause of the poor edge quality that I was seeing on parts made by the machine. Discovered I had 0.0025" of lost motion in the X- direction. This didn't show up in previous tests I had done for some reason.

I had replacement thrust bearings on hand because I knew it was a failure point on these machines, so I pulled the X axis apart and set about the replacement! It took a while because I hadn't done it before. Once I went out and bought the proper wenches it was reasonably straight forward.

Now I'm seeing only 0.0006" of lost motion which is vastly better than it was!

The ballscrew is clearly a bit worn, I will update the backlash compensation settings and see how we go, at the very least it should be much better! If necessary I will replace the ballscrew later in the year.

Getting closer and closer to starting on the first new batch of Resolutes!

#knifeclub #cnc #instamachinist

#machineshop #machinist

Photo by Aaron Gough on June 07, 2015.

See the original post and comments on Instagram

I did some tests this morning to find the cause of the poor edge quality that I was seeing on parts made by the machine. Discovered I had 0.0025" of lost motion in the X- direction. This didn't show up in previous tests I had done for some reason.

I had replacement thrust bearings on hand because I knew it was a failure point on these machines, so I pulled the X axis apart and set about the replacement! It took a while because I hadn't done it before. Once I went out and bought the proper wenches it was reasonably straight forward.

Now I'm seeing only 0.0006" of lost motion which is vastly better than it was!

The ballscrew is clearly a bit worn, I will update the backlash compensation settings and see how we go, at the very least it should be much better! If necessary I will replace the ballscrew later in the year.

Getting closer and closer to starting on the first new batch of Resolutes!

#knifeclub #cnc #instamachinist

#machineshop #machinist

Photo by Aaron Gough on June 07, 2015.

See the original post and comments on Instagram

Just a 'small' wrench.

Had to buy a 'small' wrench to do some work on the VMC.

This wrench is the perfect example of how much easier some jobs are with the right tools... I've been working to replace the thrust bearings in the VMC. Before I was trying to use a large adjustable wrench to loosen a preload nut while hanging onto the shaft with vise grips. 2 hours with no luck and I was making a real dogs breakfast of it... I finally clued in and went and bought the proper wrench. Ground some flats on the shaft I was trying to hang on to to fit a 1/2" wrench on there and then it came free on the first shot... Guess there really is a reason why we all end up with so many tools!

Photo by Aaron Gough on June 07, 2015.

See the original post and comments on Instagram

This wrench is the perfect example of how much easier some jobs are with the right tools... I've been working to replace the thrust bearings in the VMC. Before I was trying to use a large adjustable wrench to loosen a preload nut while hanging onto the shaft with vise grips. 2 hours with no luck and I was making a real dogs breakfast of it... I finally clued in and went and bought the proper wrench. Ground some flats on the shaft I was trying to hang on to to fit a 1/2" wrench on there and then it came free on the first shot... Guess there really is a reason why we all end up with so many tools!

Photo by Aaron Gough on June 07, 2015.

See the original post and comments on Instagram

Milly all cleaned up.

Finally cleaned up the air hose and data cable going to the VMC! Also installed a vacuum/blower system on the spindle. Works great for clearing chips away from the cut, but man does it ever make a mess of the shop!

#cnc #instamachinist #machining #machineshop

Photo by Aaron Gough on June 07, 2015.

See the original post and comments on Instagram

#cnc #instamachinist #machining #machineshop

Photo by Aaron Gough on June 07, 2015.

See the original post and comments on Instagram

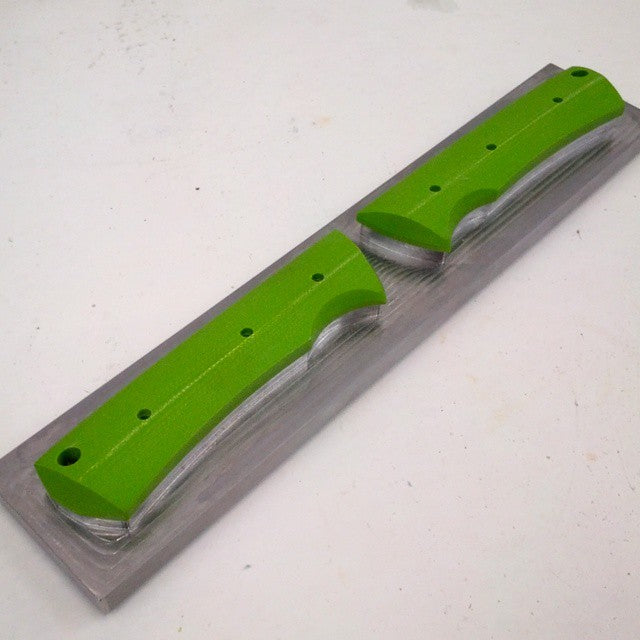

CNC machined handle scales!

Second attempt at handles scales on the machine, they're not perfect but boy are they close!

I've been sick as a dog with some sort of flu for the last 4 days, so only been working on this in between sleeping and feeling like death... Programming for these took at least 2 days, still needs refinement. The slight ridge down the middle is one of three issues that needs to be fixed. The contour over the top of the scales was cut in two passes using a modified 1" radius roundover bit... Scary to see that that big 2.5" diameter cutter closing in on the G10 block at 3000RPM!

#cnc #knifeclub #instamachinist #machineshop #usnfollow

Photo by Aaron Gough on May 26, 2015.

See the original post and comments on Instagram

I've been sick as a dog with some sort of flu for the last 4 days, so only been working on this in between sleeping and feeling like death... Programming for these took at least 2 days, still needs refinement. The slight ridge down the middle is one of three issues that needs to be fixed. The contour over the top of the scales was cut in two passes using a modified 1" radius roundover bit... Scary to see that that big 2.5" diameter cutter closing in on the G10 block at 3000RPM!

#cnc #knifeclub #instamachinist #machineshop #usnfollow

Photo by Aaron Gough on May 26, 2015.

See the original post and comments on Instagram

My first ever CNC machined knife blank!

And here she is, hot off the VMC! The first ever Resolute 4.5 blank! Hell yeah!

#knifeclub #knifemaking #customknives #customknife

Photo by Aaron Gough on May 23, 2015.

See the original post and comments on Instagram

#knifeclub #knifemaking #customknives #customknife

Photo by Aaron Gough on May 23, 2015.

See the original post and comments on Instagram

Machining the first ever blade blank!

First ever prototype Resolute 4.5 blank getting machined right now!

#knifeclub #cnc #instamachinist

See the original post and comments on Instagram

#knifeclub #cnc #instamachinist

See the original post and comments on Instagram

Taking a hefty cut on the CNC!

When everything is setup right the new machine is capable of taking a serious cut! In this case it's cutting 0.625" deep, 0.15" wide at 35 inches per minute through a bar of steel.

The crazy part is that this is not the most it can do!

I'm still very much still getting used to the amount of power and rigidity this machine has!

The absolutely mindblowing part is that my machine is generally designated as a 'light duty' machine! Its big brothers out there in the world are capable of way more!

#cnc #instamachinist #machineshop #fadal #orangevise

See the original post and comments on Instagram

The crazy part is that this is not the most it can do!

I'm still very much still getting used to the amount of power and rigidity this machine has!

The absolutely mindblowing part is that my machine is generally designated as a 'light duty' machine! Its big brothers out there in the world are capable of way more!

#cnc #instamachinist #machineshop #fadal #orangevise

See the original post and comments on Instagram