Updates

CNC smashing a drill bit...

How to break a drill bit in 3 easy seconds!

It's not always roses in my shop, little things like this are a reminder I still have a lot to learn!

What I probably should have done was to do a chip breaking cycle by dwelling every so often, or done a full retract after a slight dwell.

This was the only #7 carbide drill I had, so after breaking it I had to bust out one of my standard drills. Got the job done in a painfully slow fashion... #cnc #instamachinist #machineshop #whatnottodo

See the original post and comments on Instagram

It's not always roses in my shop, little things like this are a reminder I still have a lot to learn!

What I probably should have done was to do a chip breaking cycle by dwelling every so often, or done a full retract after a slight dwell.

This was the only #7 carbide drill I had, so after breaking it I had to bust out one of my standard drills. Got the job done in a painfully slow fashion... #cnc #instamachinist #machineshop #whatnottodo

See the original post and comments on Instagram

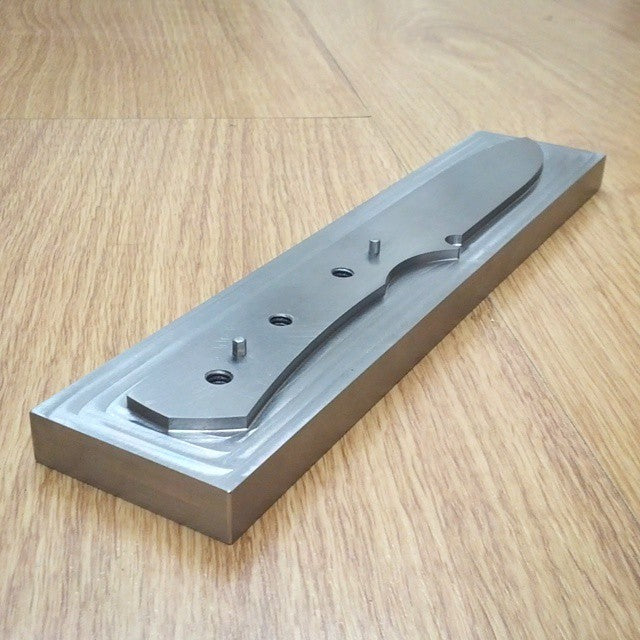

First knifemaking fixture!

Was up late at the shop last night working on this! It's a test fixture for holding the Resolute blades so they can have their outside profile cut.

First they get put in a vise where all the holes are drilled, and the handle is weight relieved, then they get mounted on this fixture and the outside profile is cut!

The knife blank is located on the fixture using two dowel pins (one round, one diamond) and then a special clamp bolts through holding it in place!

I'm feeling pretty wiped this morning, I need to start going to bed earlier than 3am, the machine is just so damn fun!

#knifeclub #cnc #instamachinist #machineshop

Photo by Aaron Gough on May 21, 2015.

See the original post and comments on Instagram

First they get put in a vise where all the holes are drilled, and the handle is weight relieved, then they get mounted on this fixture and the outside profile is cut!

The knife blank is located on the fixture using two dowel pins (one round, one diamond) and then a special clamp bolts through holding it in place!

I'm feeling pretty wiped this morning, I need to start going to bed earlier than 3am, the machine is just so damn fun!

#knifeclub #cnc #instamachinist #machineshop

Photo by Aaron Gough on May 21, 2015.

See the original post and comments on Instagram

First steel chips for Milly!

Here's a short section of the video I took yesterday! Managed to capture the first chips from the machine on film!

I love how quiet it is while demolishing the steel, absolutely amazing!

Ignore the poor chip control, I need to install an air blast system to clear the chips!

The full video is up on my Facebook page.

#cnc #instamachinist #machineshop #knifeclub

See the original post and comments on Instagram

I love how quiet it is while demolishing the steel, absolutely amazing!

Ignore the poor chip control, I need to install an air blast system to clear the chips!

The full video is up on my Facebook page.

#cnc #instamachinist #machineshop #knifeclub

See the original post and comments on Instagram

First CNC knife part!

Holy crap! It actually happened! The machine just cut its first actual part!

Pushing that big green button was incredibly terrifying! But no explosions (not even a tiny one!) and absolutely zero fuss as it went through this A2 tool steel like it was butter.

It made less noise doing this than my old bench top mill did while just running without cutting! Total time to make the cut was 4 minutes, 6 seconds... Wow. Just wow guys.

#cnc #instamachinist #knifeclub #machineshop #holyshit

Photo by Aaron Gough on May 17, 2015.

See the original post and comments on Instagram

Pushing that big green button was incredibly terrifying! But no explosions (not even a tiny one!) and absolutely zero fuss as it went through this A2 tool steel like it was butter.

It made less noise doing this than my old bench top mill did while just running without cutting! Total time to make the cut was 4 minutes, 6 seconds... Wow. Just wow guys.

#cnc #instamachinist #knifeclub #machineshop #holyshit

Photo by Aaron Gough on May 17, 2015.

See the original post and comments on Instagram

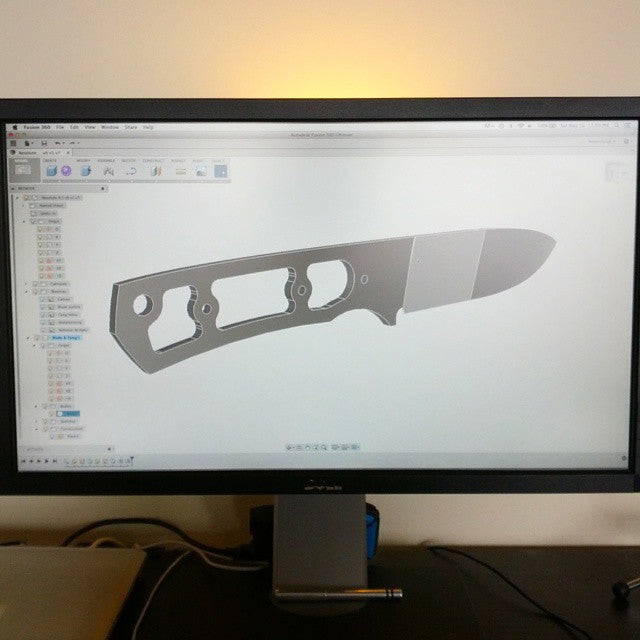

Redesign in Fusion 360

Working on modeling and design again today! Re-doing my models and learning a new CAD program called Fusion 360.

I really wanted to be able to demonstrate a CAD package in my videos that is actually accessible to others. Solidworks costs a lot of money (~$6,000) whereas Fusion 360 is only $30 per month and runs on Mac as well as Windows.

As a bonus I'm finding that I actually like modeling in Fusion better, it feels much more tactile than Solidworks. The learning curve is still there and it's a relatively new piece of software so there are still some bugs but it seems to work very well. (Just make sure to save fairly often!) They actually have a deal at the moment where you can get Fusion free for a year if you're working on an unlaunched product, so I got access for free!

The package includes integrated 2D and 3D CAM which is a massive bonus!

If you guys are interested in getting into CAD I personally think Fusion is where it's at right now. I've used Solidworks, SketchUp and some AutoCAD in the past but Fusion seems like the best fit overall for my work.

#cnc #cad #fusion360 #solidworks #instamachinist #machineshop

Photo by Aaron Gough on May 16, 2015.

See the original post and comments on Instagram

I really wanted to be able to demonstrate a CAD package in my videos that is actually accessible to others. Solidworks costs a lot of money (~$6,000) whereas Fusion 360 is only $30 per month and runs on Mac as well as Windows.

As a bonus I'm finding that I actually like modeling in Fusion better, it feels much more tactile than Solidworks. The learning curve is still there and it's a relatively new piece of software so there are still some bugs but it seems to work very well. (Just make sure to save fairly often!) They actually have a deal at the moment where you can get Fusion free for a year if you're working on an unlaunched product, so I got access for free!

The package includes integrated 2D and 3D CAM which is a massive bonus!

If you guys are interested in getting into CAD I personally think Fusion is where it's at right now. I've used Solidworks, SketchUp and some AutoCAD in the past but Fusion seems like the best fit overall for my work.

#cnc #cad #fusion360 #solidworks #instamachinist #machineshop

Photo by Aaron Gough on May 16, 2015.

See the original post and comments on Instagram

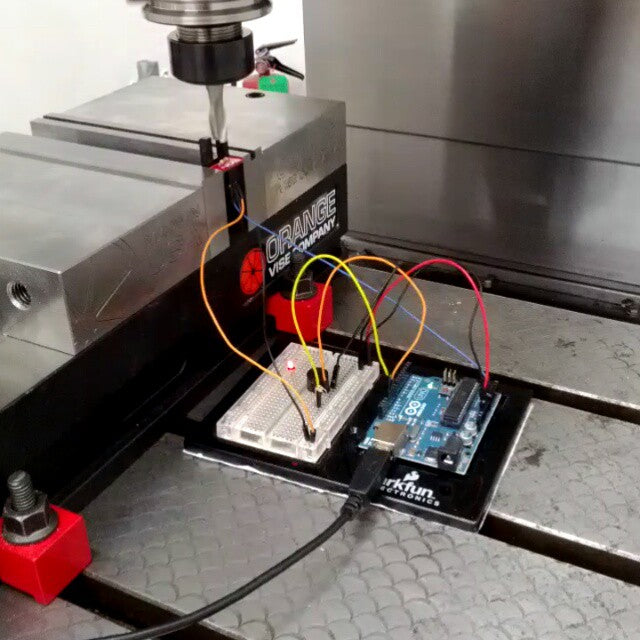

Prototype optical toolsetter!

Trying out the idea of building an optical toolsetter for my machining center. This is a super quick rough prototype using an Arduino and a cheap photo-interrupter. Seems to repeat within about 0.0002" which is pretty amazing for such a lashed up rig! Seems like it might not be a crazy idea to build one, buying one is very expensive!

The toolsetter is basically a device that talks with the CNC to accurately measure the length and diameter of your tools. They can also be used for automated tool breakage detection.

#cnc #instamachinist #machineshop #arduino

See the original post and comments on Instagram

The toolsetter is basically a device that talks with the CNC to accurately measure the length and diameter of your tools. They can also be used for automated tool breakage detection.

#cnc #instamachinist #machineshop #arduino

See the original post and comments on Instagram

First render of the Resolute MkIII

Initial design work for the new version of the Resolute happening right now!

Similar overall but lots of little improvements here and there. This is the very first render of the blade and tang. Once the first iteration of the design is complete prototypes will be made, and then the design tweaked and so on! Exciting times guys!

#knifeclub #knifemaker #knife #usnstagram #usnfollow

Photo by Aaron Gough on May 10, 2015.

See the original post and comments on Instagram

Similar overall but lots of little improvements here and there. This is the very first render of the blade and tang. Once the first iteration of the design is complete prototypes will be made, and then the design tweaked and so on! Exciting times guys!

#knifeclub #knifemaker #knife #usnstagram #usnfollow

Photo by Aaron Gough on May 10, 2015.

See the original post and comments on Instagram

Assembling my air lines.

Finally got nearly all of my air system parts! Still waiting on one little reducer bushing that will let me attach everything else to the compressor tank. That should arrive tomorrow and then I'll be good to get rolling!

Amazing how much time is absorbed by sourcing all these little parts. I reckon to date I've probably spent way more time sourcing materials, parts and equipment and setting them all up than I have actually making knives! Oh well, that's life in the workshop for you! Soon I'll be setup and then lots of work happening on jigs and fixtures for the new version of the Resolute!

Photo by Aaron Gough on May 06, 2015.

See the original post and comments on Instagram

Amazing how much time is absorbed by sourcing all these little parts. I reckon to date I've probably spent way more time sourcing materials, parts and equipment and setting them all up than I have actually making knives! Oh well, that's life in the workshop for you! Soon I'll be setup and then lots of work happening on jigs and fixtures for the new version of the Resolute!

Photo by Aaron Gough on May 06, 2015.

See the original post and comments on Instagram

Another view of the new workshop layout...

This is the new layout when looking back toward the front of the shop. Won't stay this clean for very long so I figured i should get some photos!

Photo by Aaron Gough on May 04, 2015.

See the original post and comments on Instagram

Photo by Aaron Gough on May 04, 2015.

See the original post and comments on Instagram

New workshop layout!

New workshop layout! Spent the day finishing the new workbenches that you can see here... Feels like so much more space now!

Adding more standing workbenches rather than seated benches almost doubled my storage space, and the place feels a lot more open and usable at the same time! Very pleased with how it came out. This week will see the first real use of the machining center as well! Exciting times!

#makeitbetter

Photo by Aaron Gough on May 04, 2015.

See the original post and comments on Instagram

Adding more standing workbenches rather than seated benches almost doubled my storage space, and the place feels a lot more open and usable at the same time! Very pleased with how it came out. This week will see the first real use of the machining center as well! Exciting times!

#makeitbetter

Photo by Aaron Gough on May 04, 2015.

See the original post and comments on Instagram